Pearson

Pearson has a global reputation as a builder of fine fiberglass sailing yachts – as well as a few power yachts – for many decades but few know that very early in its corporate life, in the late 1950s, Pearson also produced a handful of outboard-powered runabouts.

Pearson runabouts are almost never found in the usual old boat haunts, such as used boat yards, classified ads or eBay. In fact, since spotting mine on eBay in 2002, I have never seen another one, and when the Pearson Yacht Owners Association heard that I had a runabout, it contacted me for pictures to prove to its members that such boats were, in fact, manufactured. Mine, a 1957 model, survived because it sat in a garage in Massachusetts for 33 years after its original buyer and owner died. His widow just left it there on its trailer, with a Mark 55 Merc motor, until an old boat collector and dealer heard about it and got the widow to offer it on eBay.

I bought the boat because I liked its looks, and only later learned how rare Pearson runabouts are, largely because so few were every produced. But that piqued my curiosity and I did some research on the company – and even scored a pic of an old sales brochure, including my boat.

"I grew up in a tenant house in New York. I sold papers, all the usual stuff to hustle a buck," founder Everett Pearson said in one interview I found. "But our family also had a summer cottage where I learned to sail on an old eight-foot punt that a family friend had given us. I fixed it up and taught myself to sail. The cottage had been built in 1933 on a piece of land that my family bought in 1932 for $100 dollars. Waterfront lots went for $300, with the next lot back being $200. We ended up three lots back.

"I built my first dinghy in 1955, when I was still in college, with my cousin Clinton. Our fathers were brothers. Another friend of the family, Ted Harrison, had read an article in Popular Mechanics about boat building with a new material called polyester fiberglass. I had done a lot of wood projects with my dad while growing up but this was something new. Ted bought a drum of resin for Clint and me to experiment with. We made up the male mold, then the female mold, then attempted, five or six times, to make up a dinghy using a crude vacuum method. But we couldn't get the process to flow evenly and wound up with holes in the hull. We finally gave in and ended up laying them up the traditional way with mat and resin. I often think back and wish we had stayed with the vacuum process."

The account in a sailing publication call 48Degrees North, continued this way:

One of those first efforts, a yellow molded hull aptly named "Buttercup", was recently found, cleaned up and presented to Everett. It still floats. Within a year and a half the boys had moved up to 15' boats, all being built and sold out of their garage. "Clint and I ended up getting a line of credit from the bank for $2,500 each. That's all the bank would give us, initially. We built that up with lines of credit from our vendors."

By the summer of 1958 Tom Potter, who worked for American Boat Building in East Greenwich, asked if the cousins, now working out of an empty textile mill in Bristol, Rhode Island, would consider building a fiberglass boat that would sell for less then $10,000. Carl Alberg did the design and the Triton was born. Plans were made to introduce the boat at the New York National Boat Show in 1959, but just weeks before the show the money ran out. Desperate, Everett and Clinton went to visit Ray Pearson (no relation), the local Funeral Director. Ray, who had gone to school with Everett's mother, piled the boys into the company "van", a big black limousine, drove them to the bank and asked "how much do you need?" to which they replied "$3,500." That $3,500 was just enough to pay off the payroll and enter the boat show. The boat was a hit with 18 boats being sold. "We eventually sold about 800 or so and most of them are still out sailing - unfortunately. Turns out we built those first boats way too conservatively. And most of them are still out there sailing!"

In 1959, needing additional space, Everett and Clinton bought the Herreshoff boat building company - and the employees. "We learned a lot about the old time traditions." L. Francis Herreshoff himself came by one day to check out the new operation. "Frozen snot" was his only comment.

In 1961 Grumman Allied Industries bought a controlling interest in Pearson Yachts and the next five years were ones of steady growth for the now well-established yacht manufacturer. But by 1966 Everett was ready to leave. "I wanted to go out on my own but had to agree not to compete with my former company," which continued to carry the Pearson name, "for three years. So I decided to go into the industrial business."

(Editors note: TPI has recently purchased back the original Pearson Yacht name with plans to introduce a new line of traditional lobster-style recreation power boats.)

About the same time Everett met Neil Tillotson while helping out on Tillotson's 58-footer. Tillotson, 70 years old at the time, wanted to go into business with Pearson, suggested a 50/50 partnership and Tillotson-Pearson, Inc. was formed. Known today as TPI Composites, Tillotson-Pearson Inc. has gone on to become a major force in the industrial uses of fiberglass-reinforced composites.

"I had a business contract drawn up, but Neil never looked at it. We went for 28 years on a handshake. Our business philosophy was to employ good people, take care of our employees, and create new things." The partnership lasted until 1993 when Tillotson sold out to John Walton, son of Walmart founder Sam Walton. Now 102, Tillotson can still be reached at his office. In the early 1990s TPI was forced to revisit the vacuum system—by the EPA. "At that time we were one of the biggest emitters of VOC's (volatile organic compounds) in the state. We had been trying for some time to develop the vacuum technology, but were still working with the resin outside of the bag. A salesman from Dupont suggested we talk to Bill Seemann who had been successful in developing a closed vacuum system. I took one look and said "you got it!"

TPI bought into the patent that Bill had and now use the SCRIMP process to build all of their products; currently producing almost 300 J/Boats a year. "The SCRIMP process is consistent and repeatable—ideal for one-design boat building." SCRIMP stands for Seemann Composite Resin Infusion Molding Process. It is a closed, vacuum-assisted, resin-transfer molding (VARTM) process used for the fabrication of fiberglass products. Since 1993, TPI Composites has established itself as a pioneer in the use of the process to build, among other things, buses, wind generator blades, SwimEx hydrotherapy pools and, of course, J/Boats.

The advantages of SCRIMP "are huge," explained Jono Billings. "The fiber content of the laminate with the SCRIMP process is 70% by weight to 30% resin, with less than 1% trapped air spaces." In the world of balsa cored fiberglass boat building this is an important factor because by filling those spaces with resin you eliminate the ability for water to travel through the hull.

Equally attractive is the environmental aspect. "It's revolutionary," explained Jono, "it solves the VOC problem. Our factory employees work in street clothes, without the need for Tyvex suites and facemasks. The future, for all fiberglass manufacturing will be closed, vacuum bag, molding system. This industry needs to catch up to what Everett has been doing for years."

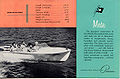

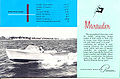

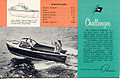

Model Information:

1958 Information

1959 Brochure:

1959 Miscellaneous

Misc Info: